LayersTech M1PRO

LayersTech M1PRO is an industrial silicone 3D printer system designed for flexible, production-ready parts—featuring smart calibration, advanced process control, and AI-assisted monitoring for repeatable performance.

- Silicone (LSR) 3D printing capability for flexible, elastomeric, production-ready parts

- High-temperature FFF/FDM printing for engineering polymers

- Industrial enclosed design for stable, consistent output

- Production workflow with smart calibration and AI monitoring

LayersTech M1PRO

LayersTech M1PRO Key Features

Built for repeatable, production-ready industrial 3D printing—stable, guided, and monitored end-to-end.

Silicone / LSR capability

Produce flexible parts with Silicone (LSR) printing capability—ideal for seals, gaskets, soft-touch components, and elastomer-like prototypes

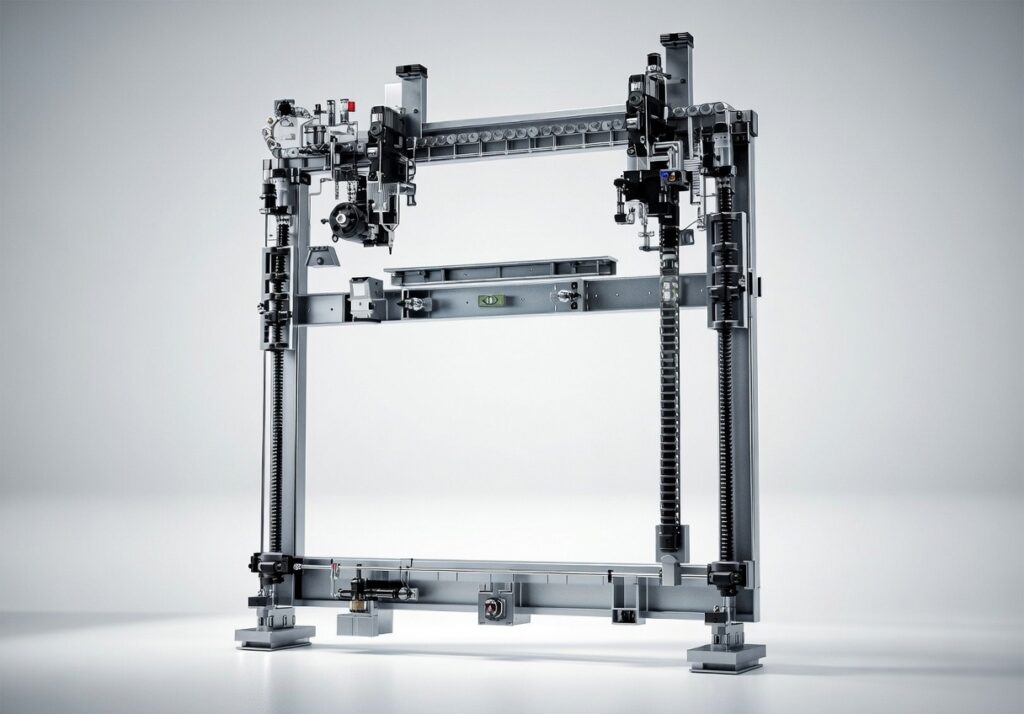

Industrial-grade build

Rigid, enclosed industrial design for stable motion and consistent print results

Reliable production workflow

Production-ready performance with repeatable accuracy and dependable thermal control

Smart, guided workflow

Guided operation with touchscreen control, automated calibration, and AI print monitoring

Advanced Silicone (LSR) Printing System

LayersTech M1PRO is engineered as a true industrial silicone 3D printer, enabling reliable Liquid Silicone Rubber (LSR) printing for flexible, functional, and production-ready parts.

The system supports precise deposition of silicone materials with different Shore hardness values, making it suitable for seals, gaskets, soft-touch components, and elastomer-like end-use parts.

Unlike conventional systems, M1PRO integrates controlled curing and multi-tool support to ensure consistent layer bonding, dimensional accuracy, and repeatable mechanical performance throughout the entire print process.

- LSR printing with multiple Shore hardness options

- Dedicated support material workflow for silicone printing

- Integrated heater rail for layer-by-layer silicone curing

- Production-ready silicone manufacturing

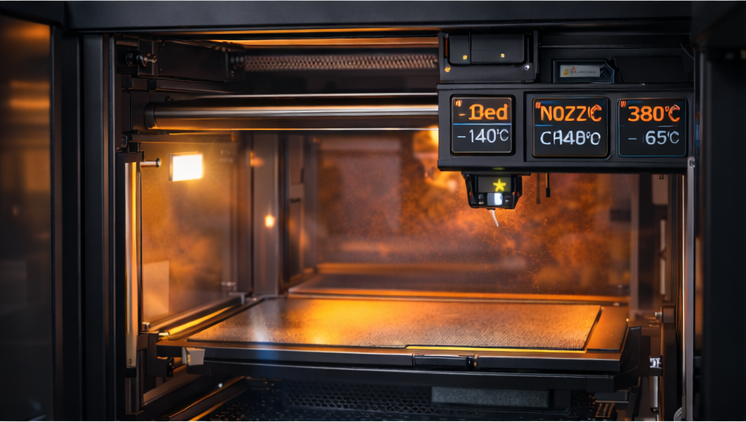

Industrial Stability, Thermal Control, Consistent Output

LayersTech M1Pro is engineered for stable, repeatable FFF/FDM production. A rigid industrial frame and enclosed chamber reduce external variation, while PID-controlled temperatures keep the bed, nozzle, and chamber steady throughout long print cycles. This results in predictable layer placement, consistent dimensions, and reliable surface finish—run after run.

- 300 × 300 × 320 mm build volume for functional parts and fixtures

- PID control: bed up to 140°C, nozzle up to 380°C, chamber up to 65°C

- Enclosed, insulated chamber for more stable printing conditions

- Enclosed, insulated chamber for more stable printing conditions

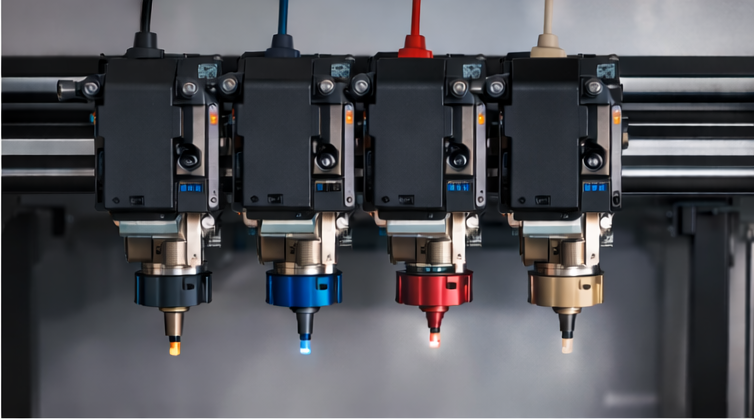

High-Throughput Multi-Material Printing (4-Tool System)

Built for speed and flexibility, M1Pro uses a direct-drive toolhead with four interchangeable tool slots—ideal for fast multi-color prints or multi-material workflows without constant manual swapping. From prototyping to small-batch runs, the system is designed to keep throughput high and downtime low.

- 4-tool workflow for multi-color or multi-material printing

- Direct-drive extrusion for responsive material control

- Optimized for repeatable production runs and continuous operation

- Compatible with additional tool types for expanding use cases

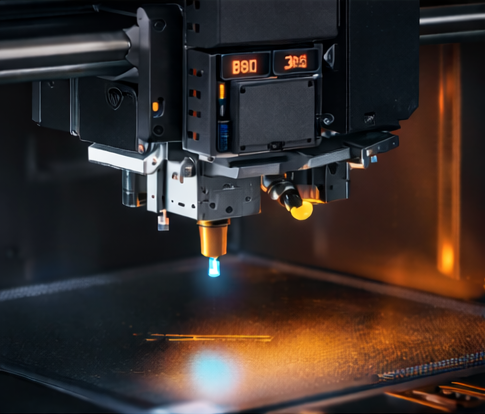

Smart Calibration: Automatic Z + Camera-Assisted XY Alignment

M1Pro reduces setup time with calibration tools designed for production. Eddy-current sensing enables automatic nozzle Z offset control for consistent first layers, while camera-assisted calibration makes XY offset alignment quicker and more repeatable—especially valuable in multi-tool configurations.

- Eddy-current sensing for automatic nozzle Z offset control

- Camera-assisted XY offset calibration for faster alignment

- Better repeatability when switching tools/materials

- More reliable first layers with less trial-and-error

AI Print Monitoring: Catch Failures Early, Save Time and Material

Production reliability depends on visibility. M1Pro’s chamber camera and AI monitoring help detect common failures—such as “spaghetti” errors—early in the process. This improves supervision during long prints, reduces wasted material, and helps teams run jobs with more confidence.

- Chamber monitoring for real-time visibility

- AI detection for spaghetti/print failure indicators

- Print cycle monitoring for better production oversight

- Supports more reliable unattended printing

Materials, Software, and Secure Connectivity for Teams

M1Pro supports a wide range of materials—from general-purpose plastics to advanced engineering polymers—backed by a modern software stack. Compatibility with popular slicers, plus secure identity and organization controls, makes it suitable for professional environments where access, accountability, and remote workflows matter.

- Materials support: PLA/ABS/PETG/ASA and engineering polymers (PA, PC, PC-ABS, PEEK, PEI, CF/GF, TPU/TPE)

- Slicer compatibility: PrusaSlicer, Orca Slicer, LayersTech Slicer

- Secure access: 2FA, organization admin roles, SSO

- Ethernet connectivity and wireless updates; remote access and camera workflow

Support & Service for Production Teams

Support that keeps production moving. LayersTech M1Pro is backed by a professional service workflow designed for industrial uptime—from onboarding and operator guidance to remote assistance and preventive maintenance planning. Teams can monitor prints via the chamber camera, manage jobs over the network, and keep systems updated through secure connectivity features.

- Setup onboarding and operator guidance

- Remote support-ready workflow with camera visibility

- Maintenance planning for long-term reliability

- Secure access controls (2FA / roles / SSO) for team environments

Material Compatibility

Supported materials for LayersTech M1 (availability depends on configuration)

SILICONE

SILICONE

PLA

ABS

PVA

HIPS

TPU

CARBON FIBER

PC

PETG

Specifications

Industrial-grade specifications for production workflows

Printer

Process

Fused Filament Fabrication, Additive Silicone Manufacturing, Additive Rubber Manufacturing

Build volume

300 × 300 × 320 mm

Bed temperature

Up to 140°C (PID controlled)

Nozzle temperature

Up to 380°C (PID controlled)

Machine weight

220 kg

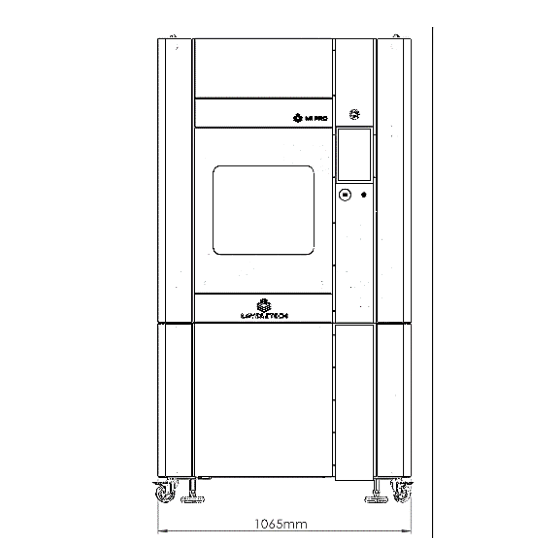

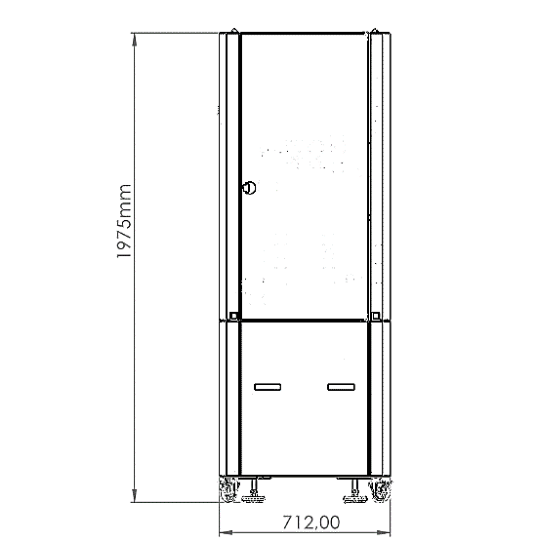

Overall dimensions

1065 × 710.5 × 1975 mm

Filtration & insulation

HEPA filter / Passive enclosure insulation (0.035–0.045 λ W/m·K)

Chamber temperature

Up to 65°C (PID controlled)

Print system

Direct-drive toolhead with 4 interchangeable tool slots; compatible with 5 additional tool types

Power

200–240V AC • Peak: 2000W • Normal (with 4 tools): 750W • With infrared: Peak 3000W / Normal 1250W

Display

10″ 720p (1280×800) touchscreen

Camera

Chamber monitoring • Spaghetti error monitoring • Print cycle monitoring

Materials

General materials

LSR Silicone, RTV Silicone, PLA, PVA, ABS, HIPS, PETG, ASA

Engineering materials

PA, PC, PC-ABS, PEEK, PEI, CF, GF, KF, TPU, TPE

Part quality

Layer height

50 μm min • 700 μm max

Accuracy

X/Y ±20 μm • Z ±30 μm

Software & security

Slicers

PrusaSlicer • Orca Slicer • LayersTech Slicer

Platform

Secure digital library, powerful slicer and printer management (premium options available)

Security

Identity & account management: 2FA, organization admin access, single sign-on (SSO)

Connectivity

Slicer connectivity and wireless updates via Ethernet • Camera (v1) • Remote access

Machine dimensions

Front view dimensions

Side view dimensions

Table of Contents

Toggle