Selective Laser Sintering (SLS) 3D printing is a revolutionary manufacturing technology in the industrial sector that enhances efficiency, reduces costs, and offers unmatched design freedom. Compared to traditional manufacturing methods, it enables the rapid production of lighter, stronger, and more complex parts.

Applications of SLS 3D Printing in Industry

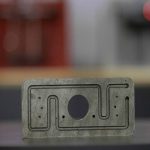

Machinery and Production Line Components

- Custom molds and fixtures

- Wear-resistant gears, bearings, and machine parts

- Precision assembly components and custom parts for robotic systems

Industrial Automation and Robotics

- Customized gripper end-effectors for robotic arms

- Durable and lightweight connectors

- Tailored parts for flexible manufacturing processes

Heavy Industry and Manufacturing Technologies

- Impact-resistant metal and polymer components

- Heat- and chemical-resistant machine parts

- Low-volume production of high-strength mechanical components

Production Line and Spare Part Manufacturing

- Rapid manufacturing of urgently needed spare parts

- Custom components that reduce time and cost in the production process

- On-site manufacturing that minimizes supply chain dependency

Advantages of SLS 3D Printing in Industry

- Lighter and More Durable Materials: SLS-printed parts can maintain mechanical strength with significantly less weight

- Improved strength-to-weight ratio compared to traditional methods

- Cost and Time Efficiency: Eliminates the need for molds, offering cost advantages for low-volume production

- Enables rapid production of custom-designed components

- Production Flexibility and Customization: Allows for the creation of complex and personalized designs

- Makes it possible to produce intricate geometries that are difficult or impossible with traditional methods

The Future of SLS 3D Printing in Industry

- Advanced Engineering Materials: Development of composites resistant to high temperatures and chemicals

- Widespread use of hybrid metal and polymer SLS printing techniques

- On-Demand Production and Rapid Spare Parts: Spare parts will be instantly produced within industrial facilities

- Production processes will be optimized through supply chain independence

Layerstech LTD continuously monitors the quality of all components at every step in the value-added chain and provides the necessary product certifications and validations. The goal of Layerstech’s 3D printing and modeling quality policy is to anticipate customer needs and future market demands and meet them through the appropriate organization, technology, and economic resources. This is the only way to ensure long-term success and competitiveness.